Understanding the range of logistics providers and their differences is crucial for selecting the best fit for your business operations. The COVID-19 pandemic has increased the need for flexible and responsive logistics in the face of supply and demand fluctuations. As a result, e-commerce businesses have started outsourcing inventory management and order fulfillment to external logistics providers in order to manage risks and navigate complexities. If you are reading this, it is highly likely that your business growth has made it necessary for you to engage with providers like Buchanan Logistics.

This article gives an overview of different logistics service models, such as First-Party Logistics (1PL), Second-Party Logistics (2PL), Third-Party Logistics (3PL), Fourth-Party Logistics (4PL), Fifth-Party Logistics (5PL), and Sixth-Party Logistics (6PL). The number of these models is growing, and sometimes they can be confusing, even for those within the industry who mistakenly identify themselves as one or the other. While some companies handle logistics internally, an increasing number are outsourcing these services with evolving organizational structures.

Among these options, let’s explore what each model entails. While Third-Party Logistics is well-known, there are also other types of providers that offer distinct roles. Especially in the field of e-commerce fulfillment, small to medium-sized businesses are increasingly turning to 3PLs in order to reduce costs compared to running their own logistics operations. This article examines the definitions and main differences among these logistics entities.

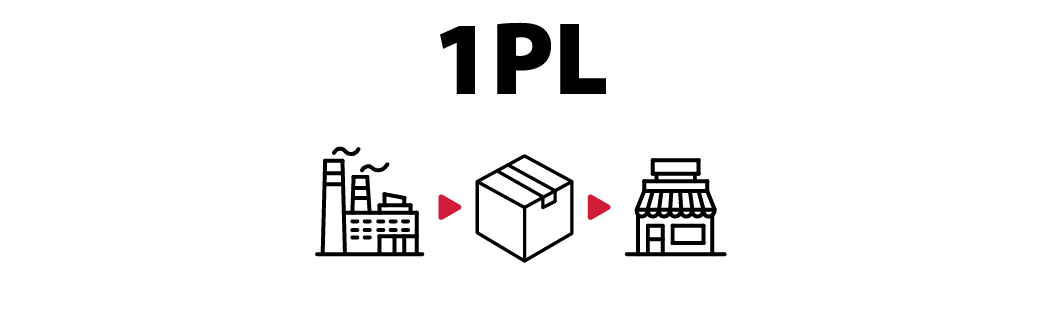

1PL - DECODING FIRST-PARTY LOGISTICS

A 1PL first-party logistics provider is an entity that handles the transportation of cargo, freight, goods, or products between different locations. This approach involves two main parties: the manufacturer or distributor who ships the goods, and the retailer or customer who receives them. There are no intermediaries involved. In the 1PL model, a company takes care of its own logistics by using its own resources and expertise for operations. This model is suitable for both small businesses with single sales channels and large enterprises with extensive logistics capabilities. This self-sufficiency is also a key characteristic of the First Party Logistic Model (1PL), where a company independently manages transportation and logistics without involving third parties.

2PL - DECODING SECOND-PARTY LOGISTICS

A shipping company or freight forwarder, known as a second-party logistics (2PL) provider, specializes in moving goods throughout your supply chain using their own ships, planes, vehicles, and transportation methods. This approach allows for the outsourcing of transport operations, whether they are domestic or international, enabling the movement of products from manufacturing or storage facilities to end customers. In the Second Party Logistic Model (2PL), the manufacturer hires a carrier or warehouse manager to handle specific transport or logistic tasks, while still maintaining overall responsibility and oversight. This type of relationship is often driven by cost and is typically short-term, with a focus on complying with client instructions. Examples of 2PLs include shipping lines, airlines, and hauling companies, which are asset-based carriers that handle various transportation methods.

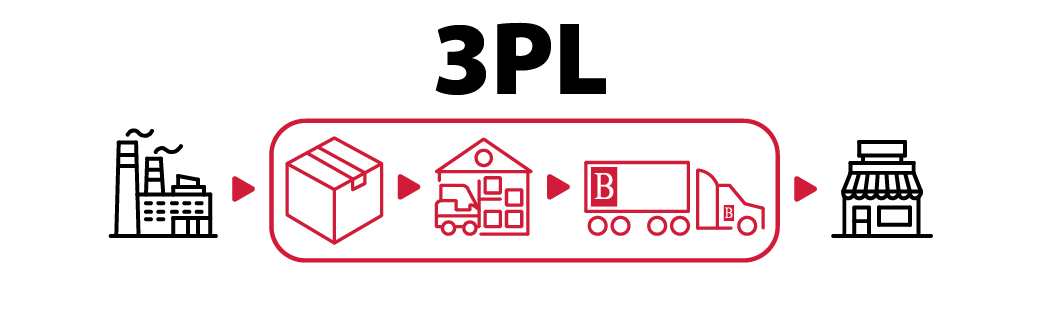

3PL - DECODING THIRD-PARTY LOGISTICS

In the 3PL model, businesses maintain control while outsourcing transportation and logistics to a supplier, who may also subcontract implementation. 3PL services support businesses by managing outsourced logistics operations, including warehousing and delivery. 3PL providers offer a comprehensive range of supply chain logistics services, such as transportation, warehousing, inventory forecasting, order fulfillment, packaging, and freight forwarding. The main advantage of partnering with a 3PL provider is their ability to effectively manage operational logistics, allowing businesses to focus on growth-related activities like sales, marketing, and product development. The 3PL industry covers distribution, warehousing, fulfillment, and value-added services like inventory management, kitting, and assembly. These providers have expanded their role alongside technological advancements such as RFID, GPS, and IoT, and are widely adopted by companies, including Fortune 500. By enhancing supply chain visibility and optimizing logistics operations, 3PL partners can improve efficiency and customer experience. They offer a range of logistics solutions, including inventory management and order fulfillment across multiple sales channels. With varying pricing structures, 3PL providers are suitable for businesses seeking optimized logistics operations while concentrating on their core strengths. Collaborating with a 3PL partner can boost logistics efficiency, enhance customer experience, and facilitate business expansion into new markets.

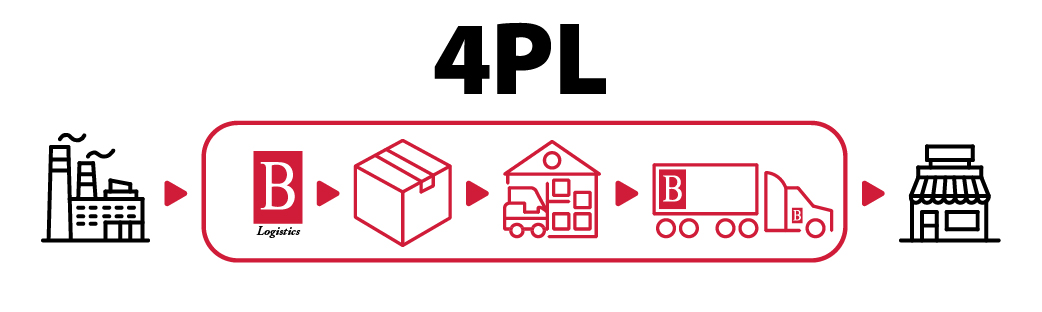

4PL - DECODING FOURTH-PARTY LOGISTICS

A provider of fourth-party logistics (4PL) offers comprehensive solutions for managing supply chains that go beyond what a third-party logistics (3PL) provider can offer. Acting as a strategic partner, the 4PL serves as a single point of contact to optimize and supervise supply chains, handle various 3PL providers and partners, and provide expertise in areas such as supply chain software and demand forecasting. This approach works well for large companies with complex global logistics operations. In the 4PL approach, logistics activities and implementation are outsourced across the entire supply chain. The role of the 4PL involves overseeing the entire supply chain and often assigning administrative tasks to different parties. Unlike asset-based logistics, 4PL service providers typically do not have their own transportation and warehouses. Instead, they deeply involve themselves in the client’s business activities, replacing short-term, cost-focused collaborations with long-term partnerships that prioritize quality and involve shared risks and benefits. By integrating and managing all resources, capabilities, and technology throughout the supply chain, a skilled 4PL provider adds value through more efficient logistics processes, centralized client communication, and a comprehensive impact on the supply chain.

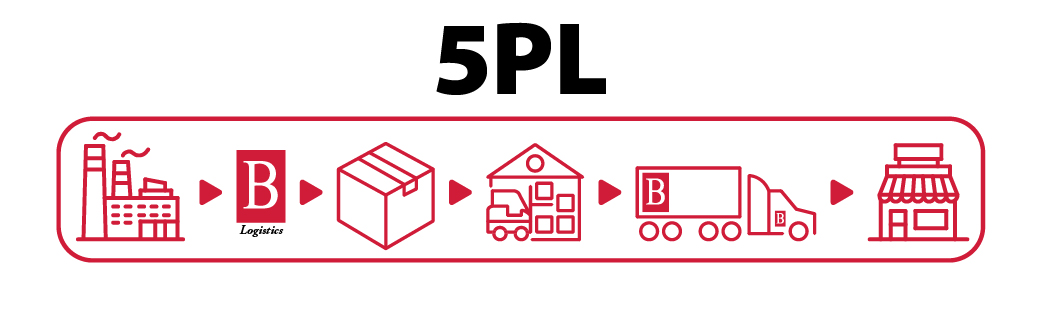

5PL - DECODING FIFTH-PARTY LOGISTICS

The logistics industry has recently adopted the term “5PL,” which refers to a comprehensive integration of logistics services by multiple outsourced providers. This approach involves fully integrated solutions that cover the entire supply chain, thanks to the involvement of various external service providers. One crucial aspect of its success is the seamless integration of IT systems, ensuring real-time visibility and control across the wide range of suppliers involved. In the world of 5PL, operators handle demand and negotiate rates with different service providers, such as trucking companies and airlines. These logistics service providers take charge of planning, orchestrating, and implementing solutions on behalf of businesses, particularly those that outsource their logistics management functions. This model has gained popularity, especially in the e-commerce sector. In addition to integrating the supply chain, 5PL entities also offer supplementary services like call centers and online payment systems. Essentially, 5PL represents a fully integrated logistics solution that spans the entire supply chain through outsourced providers, facilitated by robust IT solutions for real-time visibility. This approach, which prioritizes technology, is especially suitable for e-commerce operations.

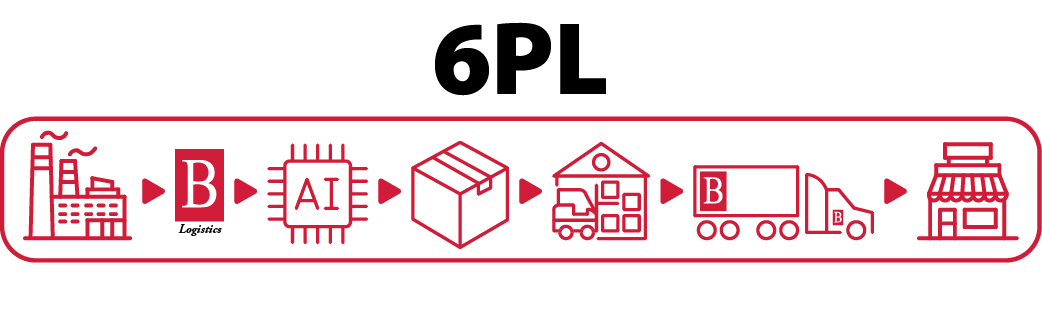

6PL - DECODING SIXTH-PARTY LOGISTICS

6PL is a somewhat theoretical concept that encompasses fully integrated, semi-automated supply chain solutions guided by artificial intelligence (AI). It is commonly referred to as “artificial intelligence-driven supply chain management.” The integration of AI throughout the supply chain has the potential to make a significant impact. Envision an all-encompassing AI system that effortlessly spans the entire supply chain, utilizing trends, ordering patterns, and predictive models to proactively issue instructions upstream. This system could instantly initiate production, provide delivery instructions, and identify anomalies. The advancements in autonomous vehicles, warehouse robotics, and delivery drones are already contributing certain aspects to this emerging concept.

Despite its advancements, AI still has its flaws. Recently, a British politician relied on patterns and algorithms suggested by artificial intelligence to run his entire campaign. However, he ultimately achieved very little success in the final results. This highlights the fact that human behavior can be unpredictable and not entirely reliable. The need for interpreting market conditions and making flexible decisions will continue to be essential.

WHAT IS THE TAKEAWAY?

There are models that go as far as talking about 10PL, but when exploring logistics service models and support options for your company, several factors come into play, such as company size, location, and future plans. You have a range of choices available, from 2PL carrier services to 4PL comprehensive supply chain optimization. The key is to find a provider that aligns with your current and future requirements. Amidst debates about 3PL vs. 4PL or 1PL vs. 2PL, it’s important to step back and evaluate your business needs. A 1PL system offers simplicity and control, but it may restrict growth beyond a certain point. Similarly, a 2PL system is straightforward but lacks the variety of solutions found in the more complex 3PL or 4PL models. Embracing a 3PL means sacrificing some control in exchange for enhanced flexibility, reach, and consistency. Choosing a 4PL involves giving up significant supply chain control as the 4PL manages and designs processes tailored to your business. Ultimately, the decision lies in finding the right balance between control and outsourced expertise that empowers your business.